Why PolyDock Connectors?

The right hardware makes the difference between a dock that wobbles and one that feels rock solid. PolyDock connectors deliver:

Full-Length Composite Design – Spans the entire joint for maximum strength and stability.

Durable HDPE Construction – Resists cracking, warping, and UV damage.

Floats if Dropped – No lost parts during installation.

Composite Connector Rods – Corrosion-resistant, long-lasting, and secure.

Stainless Steel Hardware – Built for freshwater, brackish, and saltwater environments.

Easy Install – Tightens from the top with standard tools; no special equipment required.

How Connectors Create Stability

PolyDock connectors aren’t just hardware — they’re the engineering secret behind a dock that feels safe underfoot:

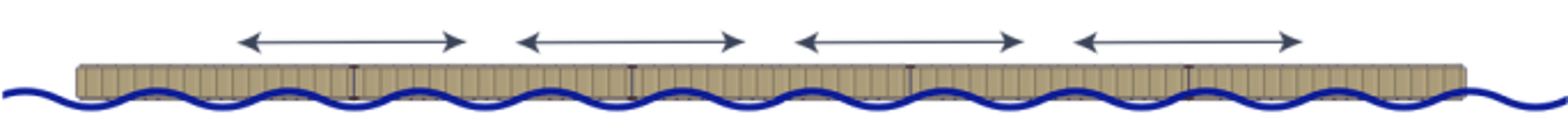

Spans the full dock joint for a secure, clean connection.

Balanced rigidity and flexibility to absorb wave action without sacrificing stability.

Multiple connection points distribute wave energy across the dock system.

Results in a firm, level surface that stays stable even in wind and waves.

“As a marina operator, the difference is obvious. Guests feel safe walking the docks, even on busy weekends. The connectors keep everything solid and dependable.” – Dana L., Marina Manager

What are PolyDock connectors made from?

High-density polyethylene (HDPE) with composite rods and stainless steel hardware — chosen for durability and corrosion resistance.

Can connectors be used in saltwater?

Yes. All materials are designed to resist corrosion and UV damage in freshwater, brackish, and saltwater environments.

Do I need special tools to install them?

No. Installation is simple — just tighten from the top using a standard wrench, ratchet, or cordless drill.

How do connectors improve dock stability?

By spanning the full joint and dispersing wave energy, connectors reduce movement and keep the dock surface flat and secure.

Can I replace a connector without removing the whole dock?

Yes. Their modular design allows straightforward replacement without full dismantling.